Simple

in installation and operation

in installation and operation

in process and detection

in design and data management

By loading the video, you agree to YouTube's privacy policy.

Learn more

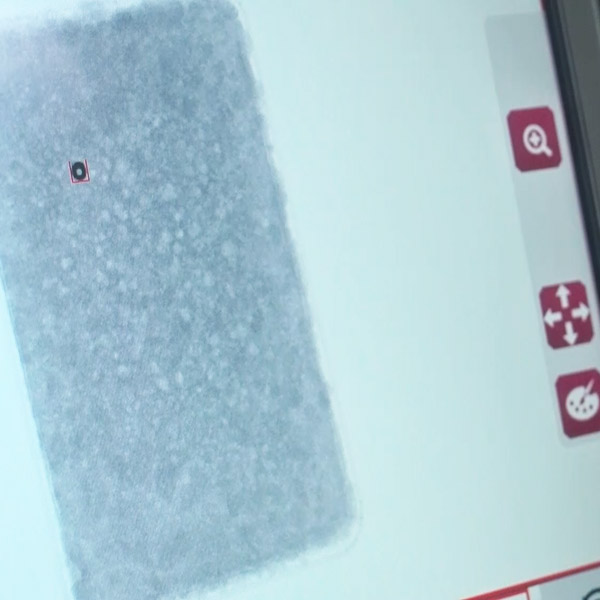

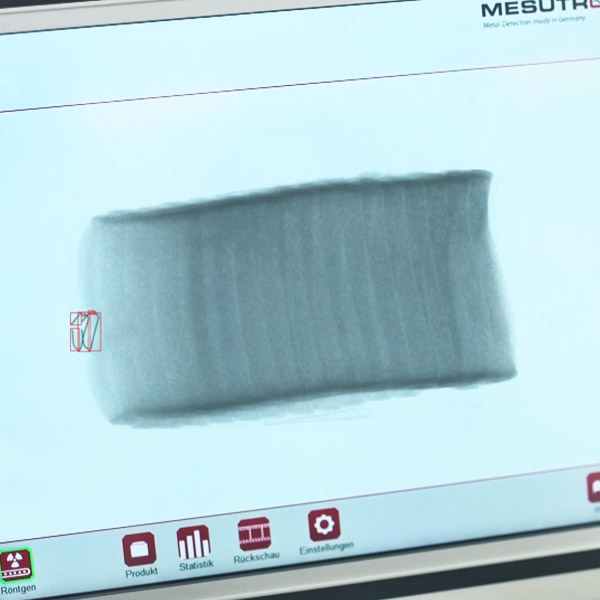

A far higher detection accuracy of stainless steel and wire-shaped contaminants, as well as the ability to detect many non-metallic impurities, such as glass, stones and high-density plastics, maximizes product safety.

Reliable inspection at the highest level is also possible with aluminum-packed products and products with a strongly fluctuating product effect.

A large number of standard quality algorithms can also be used to identify further product deficiencies. The algorithms offer, among other things, the possibility to check the units per package for completeness.

Using masking functions, one can, for example, exclude locking clips from detection and at the same time monitor them for their presence.

Even missing or damaged product parts can be easily identified using an integrity algorithm.

Simple integration is implemented by optimal consulting and project planning by a MESUTRONIC specialist on site.

Easy operation of the foreign body detector via clear and intuitive menu guidance rounds off a rapid integration of the system into the production process.

In order to minimize the maintenance effort, components such as the X-ray generator and X-ray receiver can be easily accessed from the front.

Foldable radiation protection tunnels and the belt quick release feature ensure fast access to the examination area and rapid changing of the conveyor belt.

Configurable detection test function for performance verification and comprehensive and complete data management ensure compliance with international production and retailer standards.

Due to the strict hygienic structure optimal cleaning of the system is possible.

The easySCOPE promises high flexibility through individually configurable components.

This includes different widths of conveyor belts, flexible adaptation of the system lengths to the local conditions, and product-specific reject systems such as pusher, air-jet, swivel arm or drop-flap.

The X-ray machine is the ideal system for ensuring the quality of your packaged products in the food industry. The easySCOPE detects metallic and non-metallic impurities, e.g. glass, stones or plastics, and in addition offers other useful quality control features.

The X-ray scanner offers impressive reliability and safety in the production process, while saving you time and money with its excellent price-performance ratio and easy integration.

Comprehensive data management, high-quality and low-maintenance components, as well as simple operation makes this the ideal inspection system.

in installation and operation

in process and detection

in design and data management

X-ray inspection systems have become indispensable to quality control in the food industry. Because of strict trade standards, the industry requires a more efficient methods of product control. For this reason, X-ray technology is used.

Electromagnetic waves are emitted by the generator and penetrate the product. On the opposite side, the non-absorbed radiation is taken up by the receiver diodes. The recognition of the foreign body is then carried out on the basis of the evaluation of the difference in density between product and contamination. Particularly in the case of aluminum-packed or other highly conductive products, the recognition accuracy is several times higher than that of a conventional magnetic-field-based metal detector.

The necessity for the use of an x-ray inspection system becomes clear when one considers the consequences of faulty product delivery. Recall actions and recourse claims cause high financial losses and ruin the image of a producer.

That’s why we recommend our easySCOPE x-ray inspection system!